Mining processes and the extraction of minerals can be extremely challenging due to complex geoplogical structures, varying mineral deposits and ultimately its harsh environment. Therefore, process euqipment must not only comply with strict work safety requirements but also be suitable for operations under demanding conditions. In parallel, a robust design based on resilient materials are crucial to ensure longevity of any equipment as it is in constant contact with highly abrasive materials.

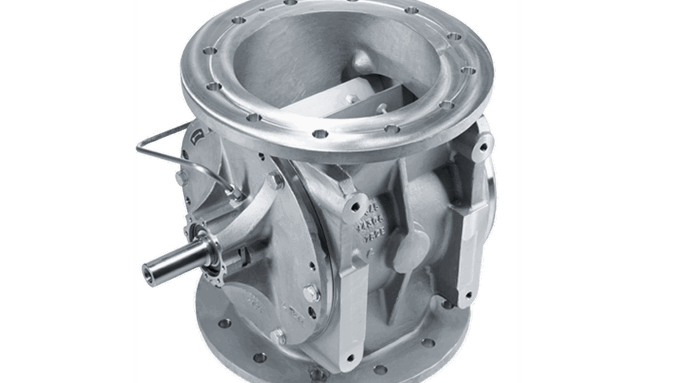

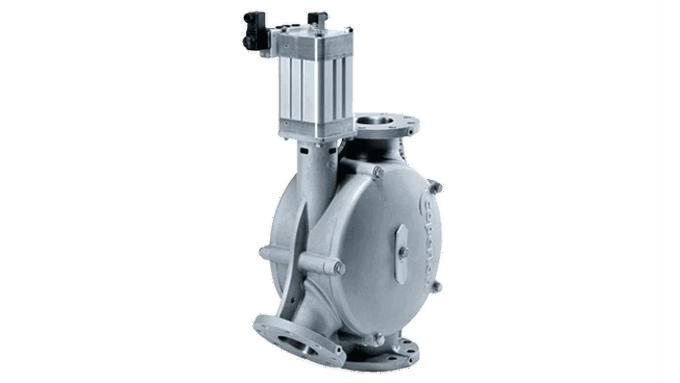

When it comes to mining and minerals, rotary and diverter valves are usually installed to control the flow of bulk materials and regulate the discharge of e.g. sand, cement or lime, from hoppers or silos. In addition, they contribute to dust prevention and provide effective sealing against leakage of the bulk material. Coperion components have a long history in the minerals industry. They meet all of the above mentioned challenges with innovative design and proven wear protection concepts which were developed based on results of comprehensive studies. With our in-house test center we are able to simulate various abrasion conditions and define the right measures for your application.

High-class Components

Open navigation

High-class Components

Open navigation