First-Class Technology for the Bottle-to-Bottle, Bottle-to-Fiber and Bottle-to-Film Process

Polyethylene terephthalate (PET) is a high-value material that is on course to take over a key function in the plastics industry’s path toward a circular economy. PET plays an ever more important role in recycling, due to the large volume of packaging materials in use today. PET posses extremely good properties for reprocessing. Its continuously expanding use in single- and reusable bottles, as well as its recovery via deposit systems, add to its value. Correspondingly, it can be lucrative for companies to focus on PET recycling.

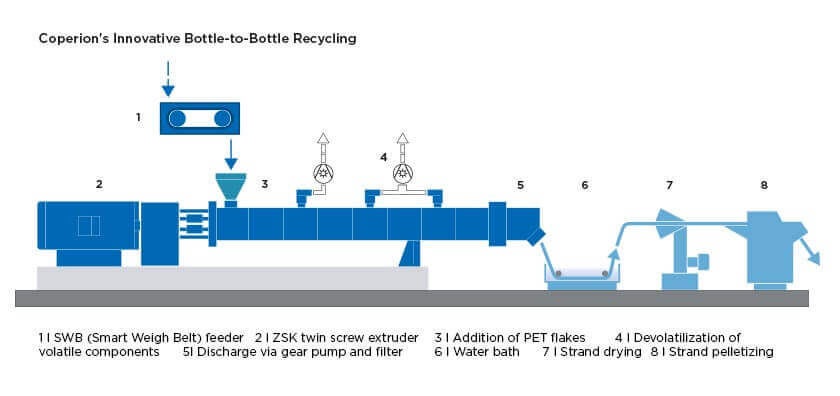

Before PET can be reprocessed, it must first be shredded to flakes and then cleaned. Ordinary technologies require pre-drying and crystallization of the PET flakes following washing. However, using the specialized technology from Coperion, the shredded PET can be fed directly into the ZSK twin screw extruder and compounded.

Thanks to the highly efficient plastification within the ZSK extruder, Coperion systems for PET recycling achieve throughput rates up to 8 tons per hour, therefore recycling companies profit from very high product quality, operating and energy cost savings, and reduced logistic expense in comparison to conventional PET recycling methods.

Coperion

Open navigation

Coperion

Open navigation