The Coperion Difference

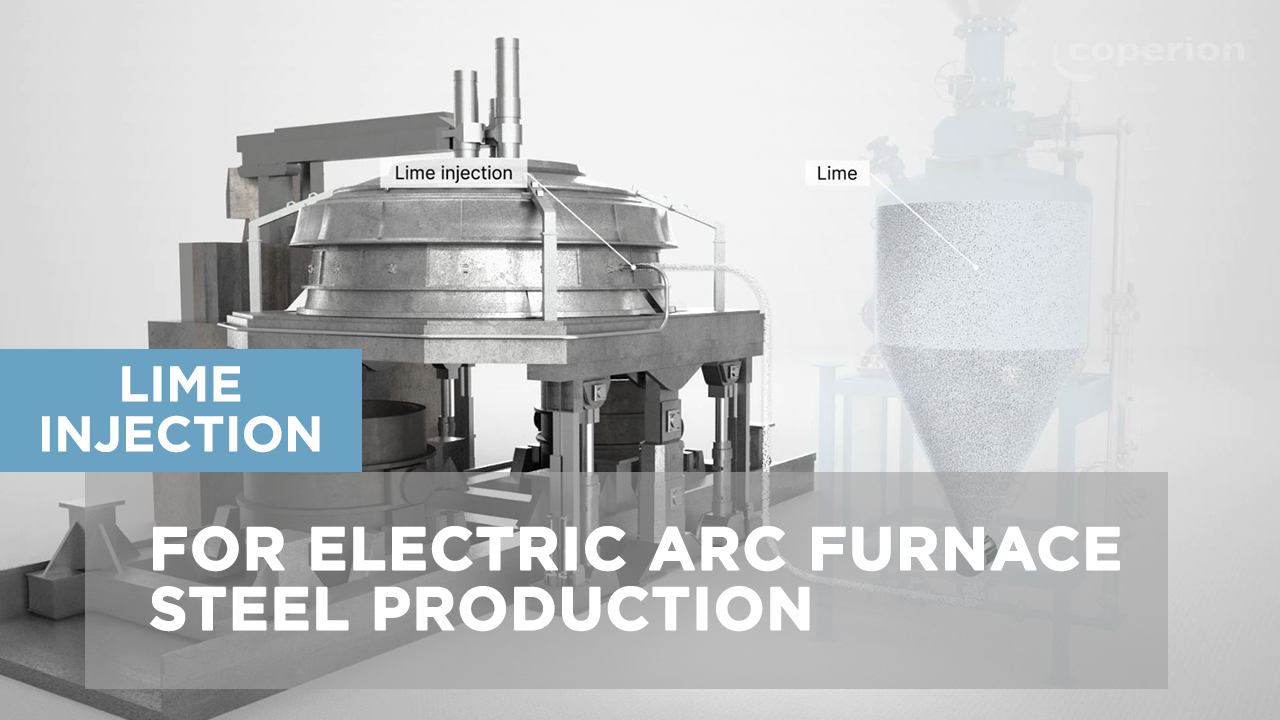

We offer innovative technologies for direct injection of carbon and lime into the furnace. This allows the furnace to be kept closed, avoiding heat loss and thereby reducing energy consumption while also removing personnel from close proximity for greater safety. Injected carbon also reacts faster and more efficiently, lessening the time needed for the overall process—and with it, the need for energy to melt the steel. Research has also shown that the lime foam created by direct injection may act as an insulator within the furnace, further boosting efficiency.

Enabling environmental innovation

We have extensive experience in the production and use of biocarbon in steelmaking, in the form of biochar that can replace the use of mined, non-renewable metallurgical, or coking, coal.

The large-scale, custom-built calciners at the center of our biochar solutions use pyrolysis: the heating of wood without oxygen, which decomposes the complex organic compounds in the wood and produces a char rich in carbon content.

This emerging technology delivers multiple sustainability benefits by using renewable materials instead of fossil fuels as a source of high-quality carbon—and our solutions are able to use waste byproducts of the pyrolysis process itself as fuel, further reducing the carbon footprint.

Tailored, tested solutions

Custom manufacturing coupled with our end-to-end collaborative engineering approach yields efficient, fit-for-purpose solutions.

Expertise in relevant technologies

We are industry leaders in lime and carbon injection, and have extensive experience in the production of biochar as a renewable, lower-impact form of carbon.

Dependable results

The repeatable accuracy of our feeding solutions helps to ensure efficient use of raw materials, reducing waste and cost by eliminating the need to overfeed.

Coperion

Open navigation

Coperion

Open navigation