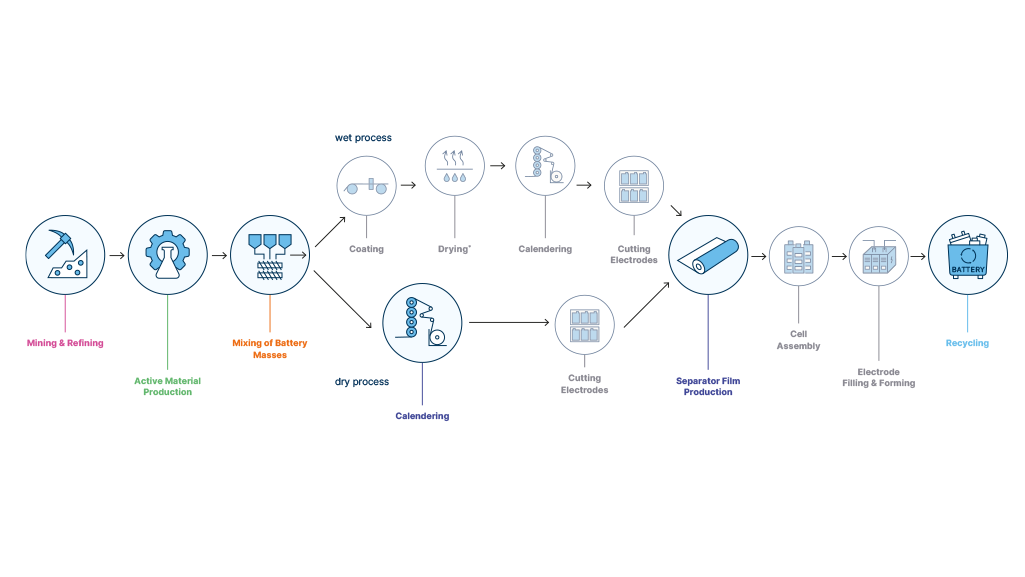

Coperion provides cutting-edge equipment and system solutions for battery manufacturing, enabling high-quality, efficient, and cost-effective production. From individual components to complete, custom-engineered systems, our technologies are designed to optimize various stages of battery production. With decades of process expertise and global reach, Coperion is the trusted partner for battery manufacturers seeking reliability, precision, and optimized workflows.

Ask the Expert

13 Nov 2025

Coperion

Open navigation

Coperion

Open navigation