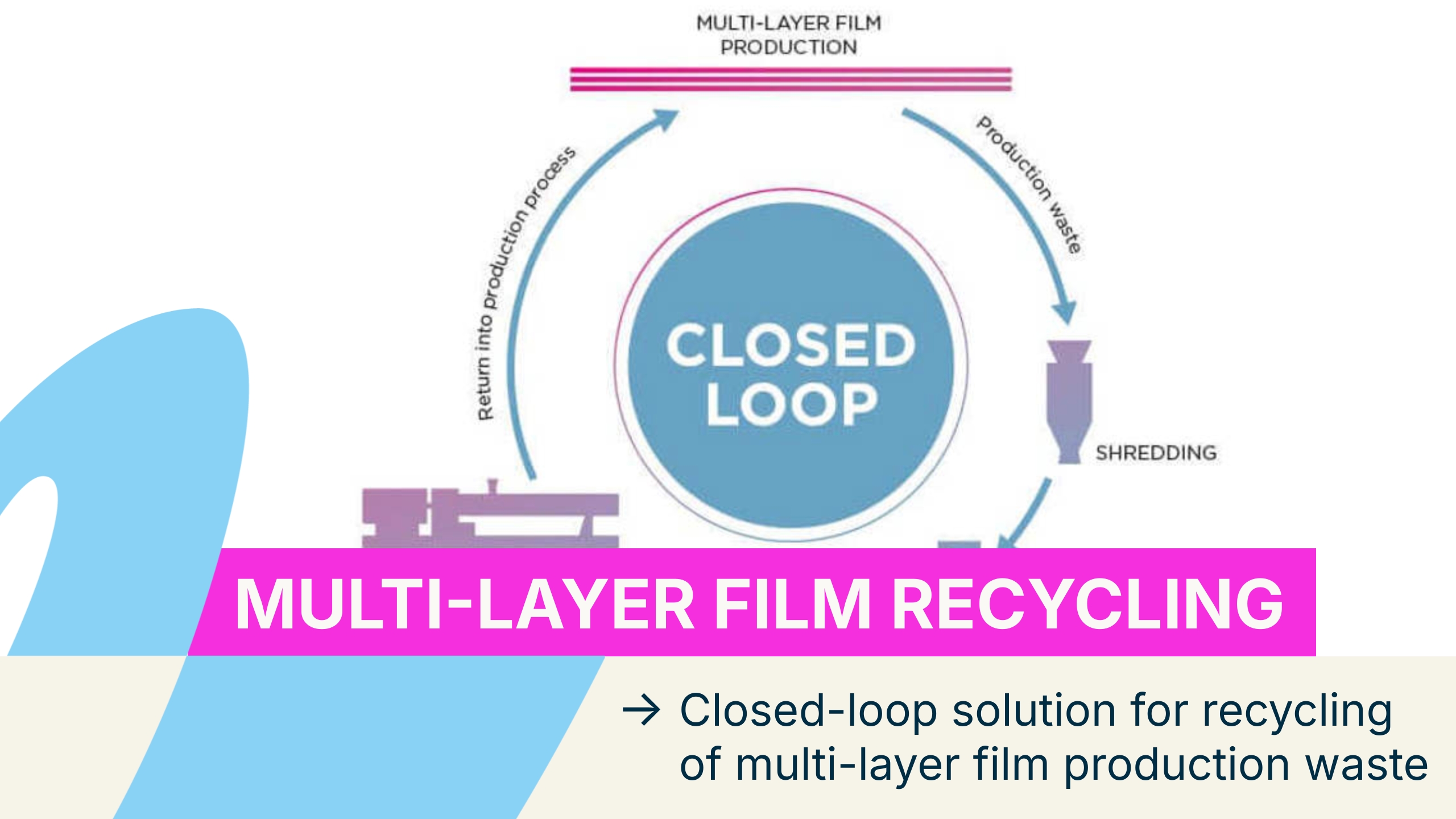

Closed-Loop Solution for Recycling of Multi-Layer Film Production Waste

Recycling multi-layer film has long posed a challenge since such films can only be reclaimed in very complicated ways and not without residues. Coperion has developed a closed-loop approach solution in which up to 100 percent of multi-layer film production waste can be re-processed and fed back into the production process in a closed-loop.

For this process, multilayer film waste is pneumatically conveyed and fed into the ZSK extruder via high-accuracy Coperion K-Tron feeders. Within the ZSK twin screw extruder, it is intensively dispersed and degassed. Subsequently, the high-quality melt can be fed back into the multilayer film production process.

Coperion

Open navigation

Coperion

Open navigation