High-capacity extruders for polyolefins

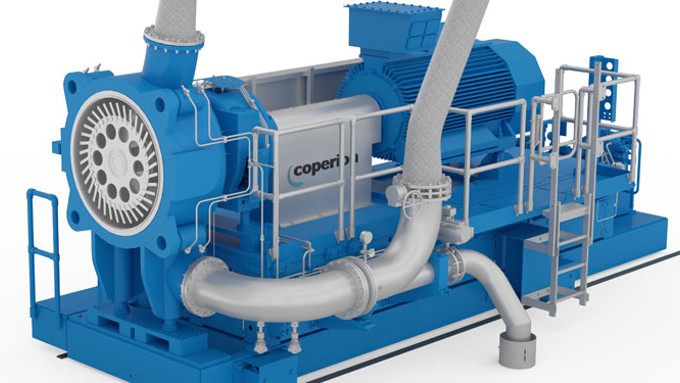

The twin screw extruder ZSK MEGAcompounder from Coperion is considered a milestone in the development of the high-performance compounding plants for the production of polyolefins. The extremely high productivity of the system is the result of Coperion's continuous research and development.

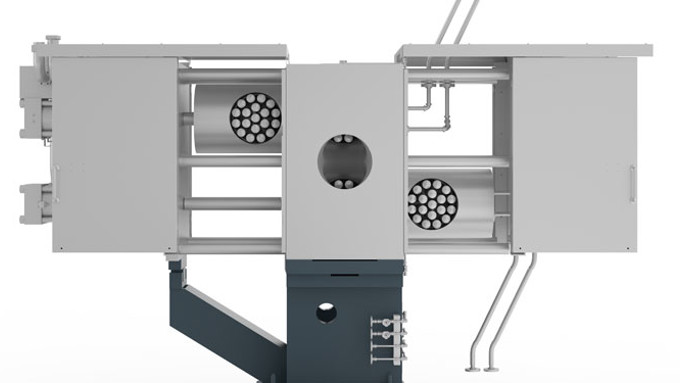

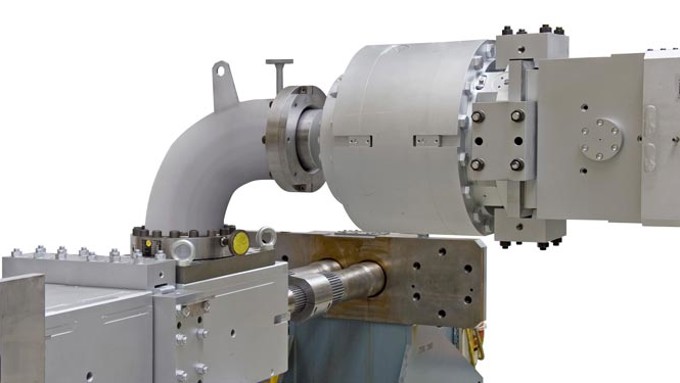

The ZSK MEGAcompounder is a closely intermeshing, co-rotating twin screw extruder, providing highest throughput rates and productivity. The modular design of the process section allows various zones to be configured as required for conveying, plasticizing, mixing and shearing, homogenizing, devolatilizing and pressure build-up. The ZSK achieves maximum throughput rates and first-class compound qualities with

outstanding process reliability.

Whether it is a matter of compounding and pelletizing of polyolefins, discharge of LDPE/EVA from LPS, devolatilization of polymer and rubber solutions or processing of bimodal polyethylene with our many years of know-how we configure the ZSK MEGAcompounder and the system's auxiliary equipment to your individual process requirements. You achieve maximum throughput rates with the greatest possible cost effectiveness and the highest product quality.

The current series features a specific torque of 12.5 Nm/cm3. This brings polyolefin processing to throughput rates of up to 135 t/h.

Coperion

Open navigation

Coperion

Open navigation