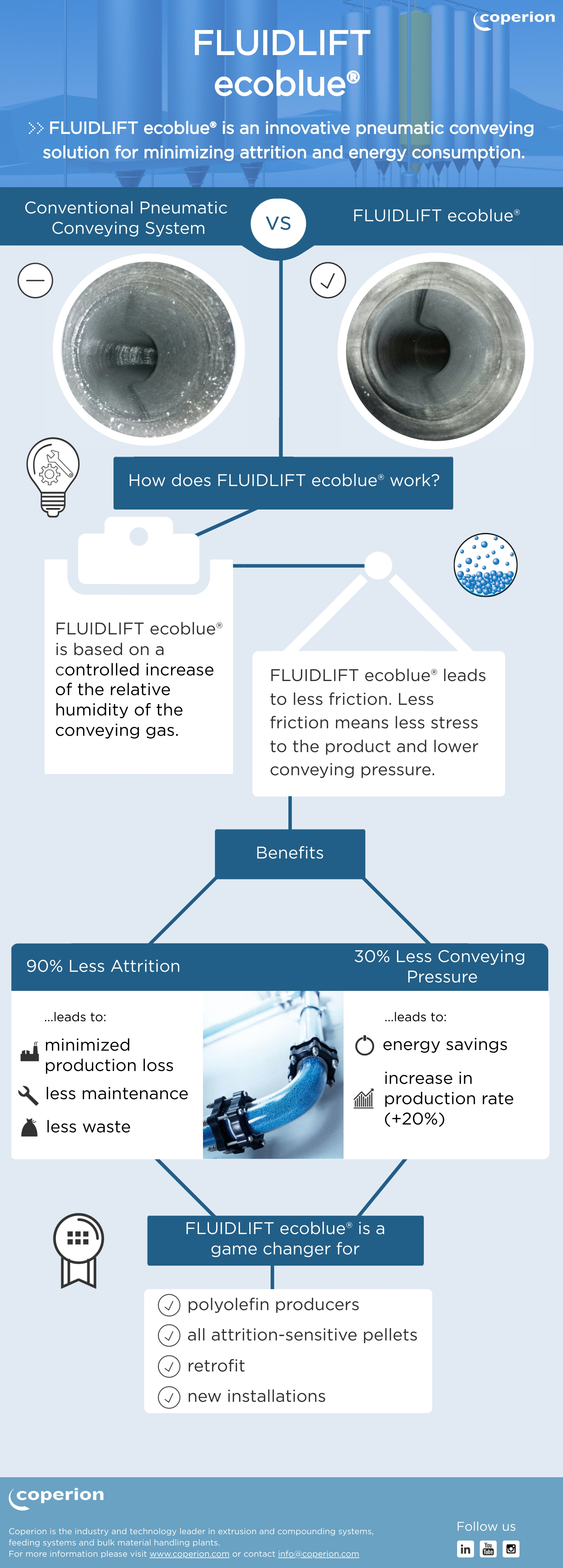

Unlike conventional designs, FLUIDLIFT ecoblue® has proven to be an effective solution when it comes to avoiding dust as well as streamers in pneumatic conveying systems. The positive effect is achieved through an increase of the relative humidity of the conveying gas in a controlled environment. This additional moisture is then reliably removed and does not interfere with the end product. As a result, granules are smoothly conveyed at a much lower velocity causing less friction between grains or through the walls of the pipes.

Overall, FLUIDLIFT ecoblue® has shown a decrease in attrition of up to 90 percent and a reduction of the conveying pressure of about 30 percent on average. Thanks to circumventing the root cause of friction, manufacturers benefit from a reduction in production loss and hence produce less waste. At the same time, the conveying system requires less maintenance as the pipes remain in a better state. In parallel, the reduced conveying pressure contributes to substantial energy savings and helps to increase the potential of debottlenecking by up to 20 percent.

Therefore, this flexible add-on technology is a game changer for all attrition-sensitive pellets. Especially polyolefin producers and compounders will see a major improvement in their daily operations. FLUIDLIFT ecoblue® is not only suitable for new installations, but is also a useful extension when retrofitting an existing plant. The solution can be used in all climate zones.