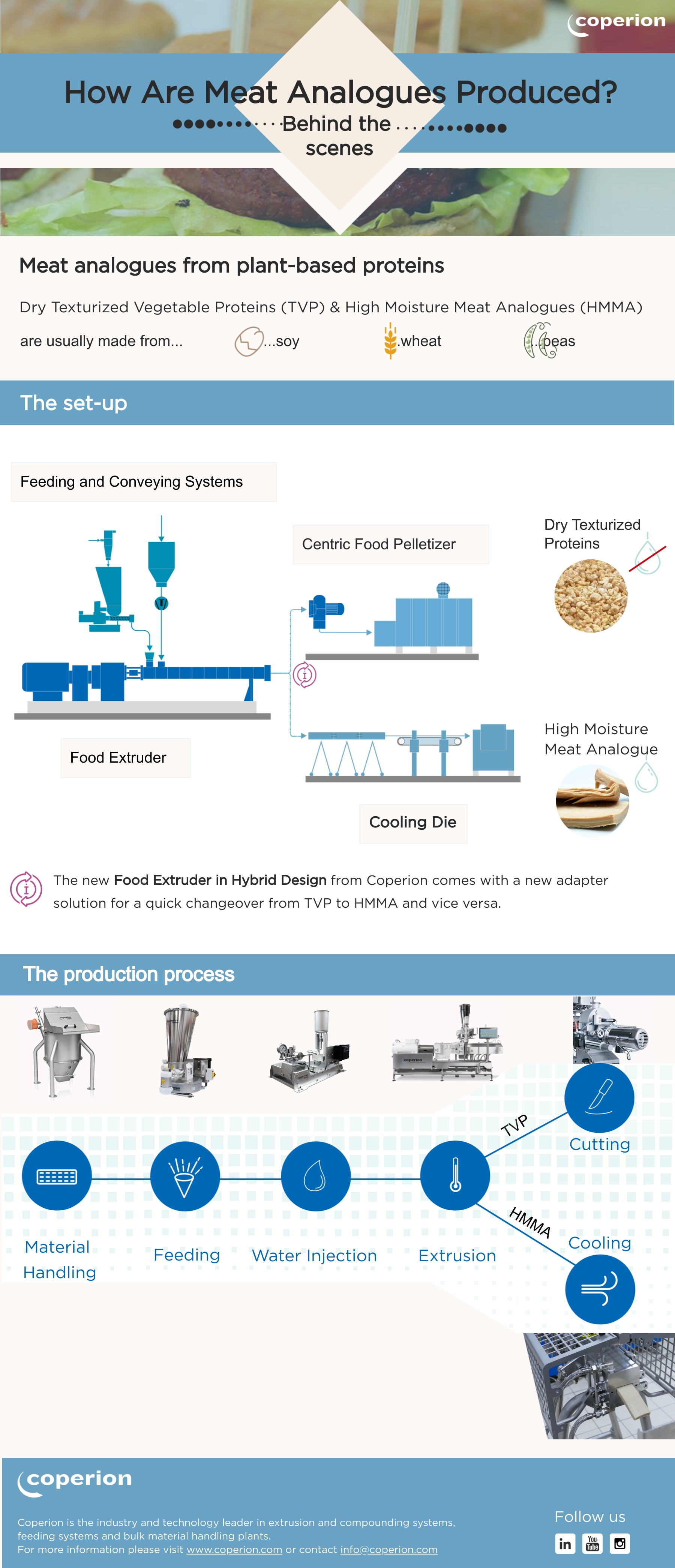

But what does the production process look like? And what is the difference between Texturized Vegetable Proteins (TVP) and High Moisture Meat Analogues (HMMA)?

Get a glimpse behind the scenes in the following infographic:

Coperion

Open navigation

Coperion

Open navigation

But what does the production process look like? And what is the difference between Texturized Vegetable Proteins (TVP) and High Moisture Meat Analogues (HMMA)?

Get a glimpse behind the scenes in the following infographic:

Even though meat substitutes are available in numerous forms and consistencies, they are mostly based on two types of plant-based proteins: Texturized Vegetable Proteins (TVP) and High Moisture Meat Analogues (HMMA).

TVP is known for its dry consistency and long shelf life when stored under normal ambient conditions. It is mostly offered as crumbles, flakes or even strips. As a result it is suitable for several dishes ranging from the classic spaghetti Bolognese to vegan chicken breast. When preparing TVP-based products, they need to be soaked in water or liquid as TVP requires hydration before use.

HMMA on the other hand is characterized by its high proportion of moisture. It typically consists of 50-80% of water which is about the same as lean meat. Therefore it is used for many ready-to-eat meat dishes.

Both TVP and HMMA are manufactured using accurate feeding systems and a food extruder. When the melt discharges from the extruder, the set-up significantly differs from one another. While TVP is released and directly cut at the nozzle plate, HMMA requires a special cooling die. In the cooling die the material is cooled down while being forced into a laminar flow. This way, a meat-like structure is created.

Originally, the set-up required two different systems. Since food manufacturers require more flexibility, Coperion has developed an adapter solution to quickly change the same base system from TVP to HMMA and vice versa. As a result, food producers can now use the very same food extruder for both applications.

This video shows the extrusion of HMMA in Coperion’s test lab.

Advanced systems design for material handling, feeding and extrusion.

Find smart feeding solutions for your food application.