RotorCheck 5.0 is an add-on solution for Coperion’s rotary valves which detects, evaluates and reports unintended contact between the rotor and the housing.

Learn more about the advantages of RotorCheck in the following infographic:

Coperion

Open navigation

Coperion

Open navigation

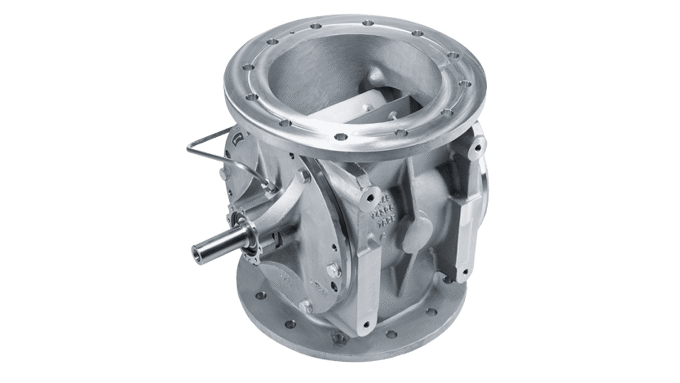

RotorCheck 5.0 is an add-on solution for Coperion’s rotary valves which detects, evaluates and reports unintended contact between the rotor and the housing.

Learn more about the advantages of RotorCheck in the following infographic:

By constantly monitoring contact between the rotor and housing, RotorCheck 5.0 helps to prevent metallic abrasion. Therefore, food manufacturers have high control over the product being conveyed and can reliably avoid potential contamination. Thanks to the flexible control system, the device can be adapted to changing production conditions. In this connection, the parameters of the device can be easily adjusted to product properties or varying cleaning cycles. Another advantage is based on the diagnosis interface of the contact monitoring system. Both the settings and the analysis data are accessible via a web interface through which operating RotorCheck 5.0 becomes very convenient and easy. Moreover, the control center is permanently accessible even when the production area is not, e.g., for safety reasons during a CIP-cleaning. As a result, operators are always in full control over the production process.

On the basis of these advantages, RotorCheck 5.0 is especially suitable for food manufacturers with high requirements in terms of product quality and product safety. At the same time, this add-on can be extremely beneficial in the context of regular product changes, or if frequent cleaning cycles are necessary.

As the infographic shows, the visualization in the process control center is simple and easy to understand. Whenever there is a short or long metal contact the system sets off an alarm.

Rotary valves from Coperion and Coperion K-Tron come with the reliability of decades of experience, know-how and proprietary development, and manufacturing with top quality materials.

Coperion offers tailored solutions for the food industry – from single components to complete systems.

The systems engineers at Coperion and Coperion K-Tron can help to design the optimal ingredient transfer system for your operation.