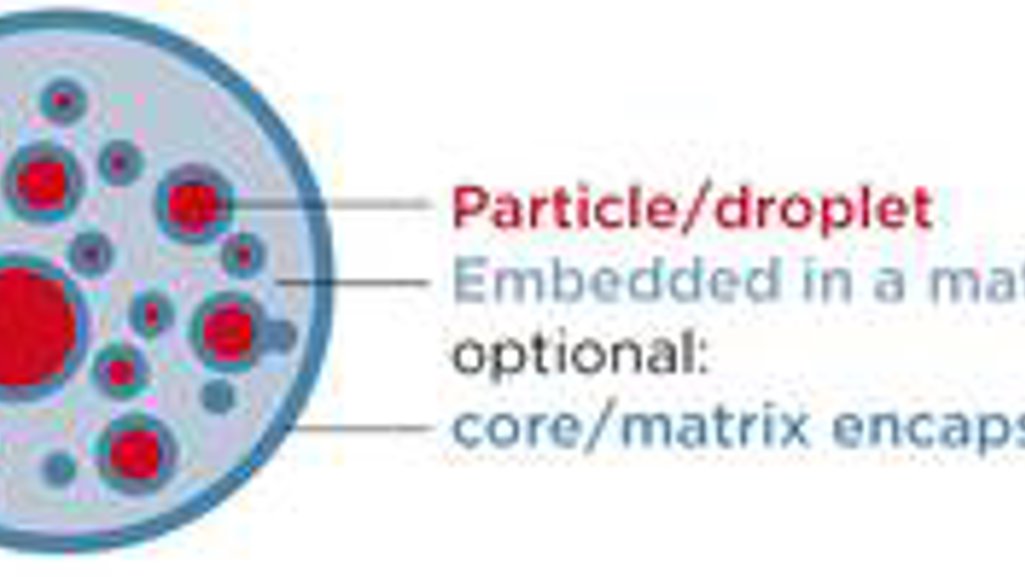

Encapsulated active ingredients and additives are becoming increasingly important in many areas of application. Encapsulation is to be understood as all procedures for the complete envelopment or embedding of liquid drops, solid particles or also gases in a solid enveloping substance (matrix). Core material and matrix are not mixable with each other. The main reason for the encapsulation is the protection of the core material against damaging influences such as light, oxygen and moisture. In addition, nutritional and health issues may be in focus to release ingredients at specific places in the digestive tract or with delayed action. But the largest area of application is most probably the encapsulation of flavors to guarantee optimum taste experience at the time of eating.

Sign up for the Coperion newsletter to receive the latest updates

Enveloping to size

Extrusion for encapsulation of active ingredients and additives

Spray drying and extrusion are the encapsulation methods most frequently used in food processing - whereby extrusion with the co-rotating twin screw extruder ZSK has a number of advantages over spray drying. In the ZSK extruder, the encapsulation takes place in a highly viscous medium; there is no complex, product-damaging and uneconomical redrying step. In addition, the temperature control in the extrusion process can be selected independently of evaporation temperatures of solvatation agents (usually water). The substance to be encapsulated is normally not added until after formation/structuring of the envelope matrix. There is also a wide choice of possible matrix materials. Extruded capsules are completely surrounded by the enveloping substance with the exception of the enclosures touching the pellet surface. Unlike spray-dried products, they can be moistened well without further agglomeration steps.

In the extrusion process, powder is fed into the process section of the ZSK first, usually a hydro-colloid or a suitable premix with film-forming properties. Water or softeners are added downstream as required and later the product to be encapsulated. A homogeneous, highly viscous, low water mixture of core material and envelope matrix is created with different process steps such as mixing, kneading, cutting and heating in the process section of the ZSK which usually only requires little drying or cooling afterwards. The melt is cut into solidifying pellets by means of the concentric pelletizer ZGF directly after being discharged from the nozzle. In this way, spherical or elliptical products from a diameter of 0.5 mm that are mechanically stable can be produced. They have a load of below 10% to max. 25%. Post-treatment of the surface is possible to remove free drops/particles. Depending on the machine size, throughput rates of 1 to 10 kg/h in the laboratory and up to several 100 kg/h on a production scale can be achieved by extrusion.

Coperion has long years of experience and extensive knowledge in the development of extrusion systems for the encapsulation of solids and liquids such as flavors, vitamins, feed additives or pharmaceutical ingredients. The intensive mixing behavior of the ZSK twin screw extruder ensures a highly dispersive distribution of the ingredients. At the same time the kneading and mixing take place in the process section of the ZSK with low shearing and low temperature so that highest product qualities are achieved. The continuously operating extrusion system is completely enclosed and therefore offers hygienic advantages. The process section has a modular structure consisting of individual barrels and screw elements and is used in different sizes for a wide range of applications - among other things for micro-incapsulation.

-

Stefan Gebhardt

- email: stefan.gebhardt@coperion.com

- telephone: +49 (0)711 897 3048

Coperion

Open navigation

Coperion

Open navigation