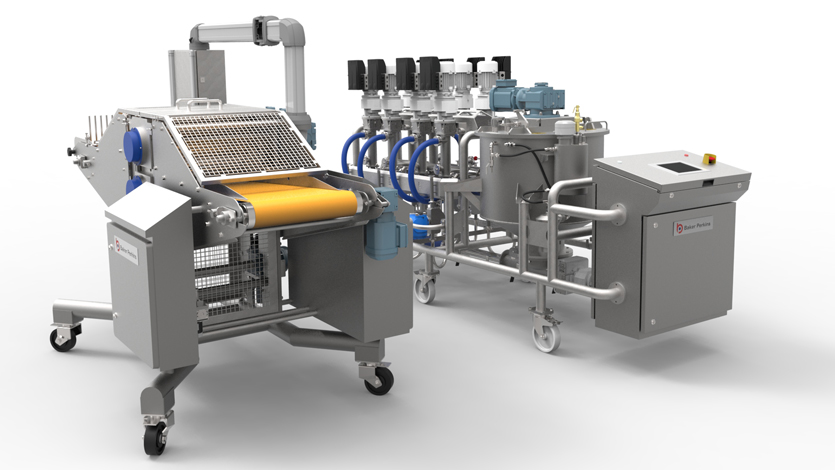

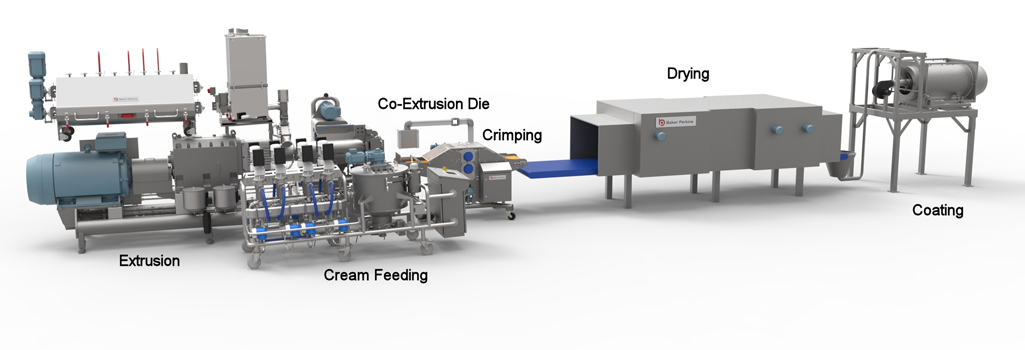

A crisp outer shell with a tasty cream or paste filling adds value and variety to extruded food and pet food products. Attaching a co-extrusion system to a twin-screw extruder is a low-cost way for manufacturers to add high-value creations to their range of breakfast cereals, snacks or pet treats while retaining the flexibility to make a full range of standard products.

The latest end-product innovation is the twin-filled tube. This tube has two separate fillings of the same or different creams or pastes. It can be used for classic combinations such as strawberries and cream or cheese and tomato, or taste sensations such as spicy curry and cooling yoghurt.

Coperion

Open navigation

Coperion

Open navigation