Highly Flexible Technology for the Production of Plant-Based Proteins

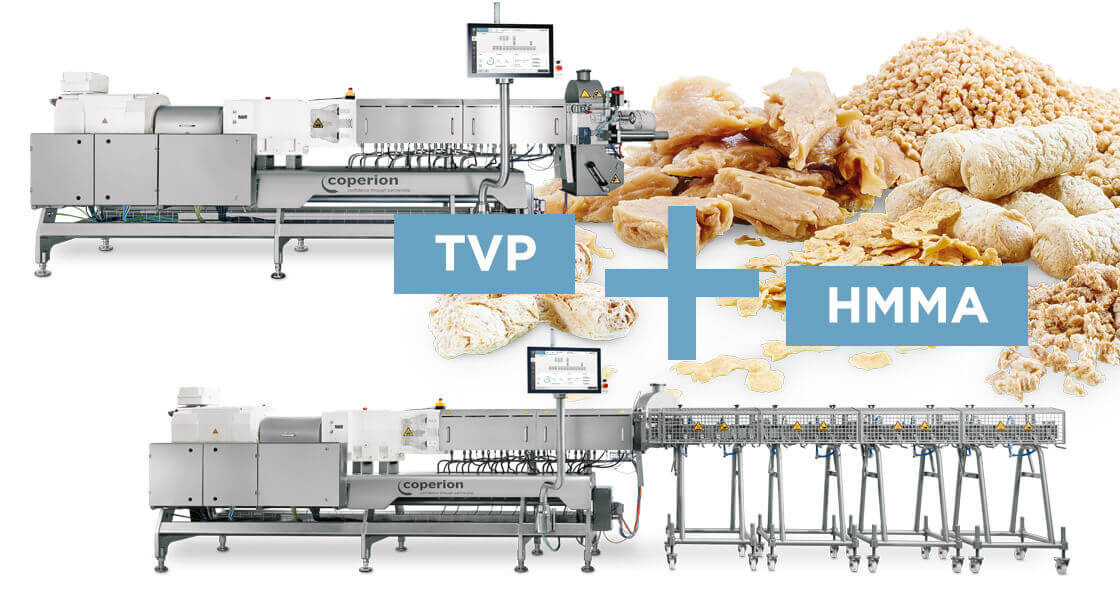

Coperion’s ZSK Food Extruder in Hybrid Version offers manufacturers of meat substitutues the benefit of rapid switching between TVP (Texturized Vegetable Proteins) and HMMA (High Moisture Meat Analogues) production. The system provides maximum flexibility to be able to profitably react to changing market demands for meat analogues, even on short notice.

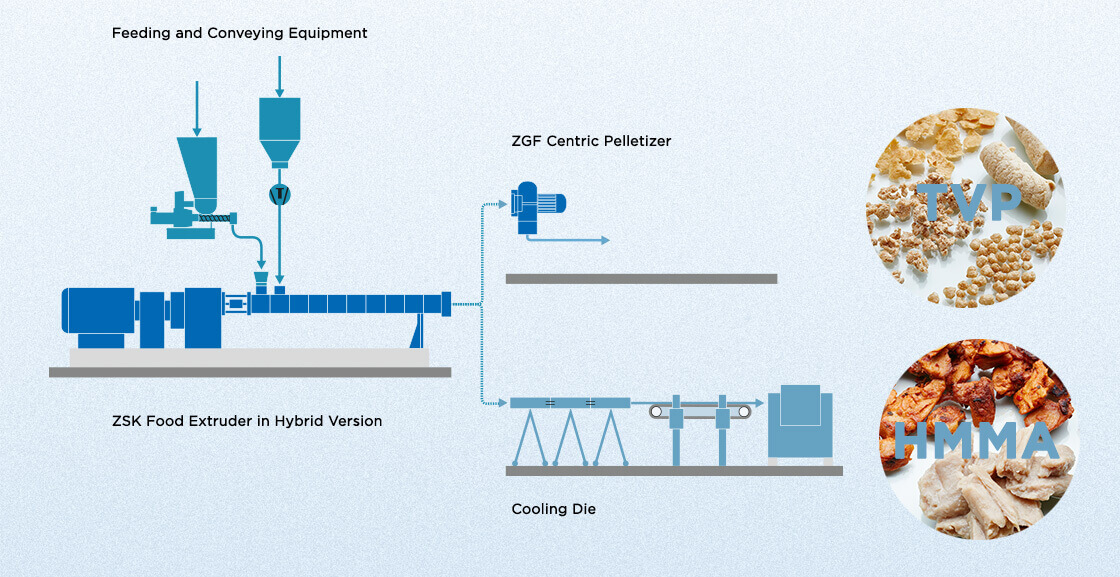

Both processes use the same ZSK Food Extruder, but final product structure is achieved either via the ZGF centric pelletizer for TVP or a cooling die for HMMA.

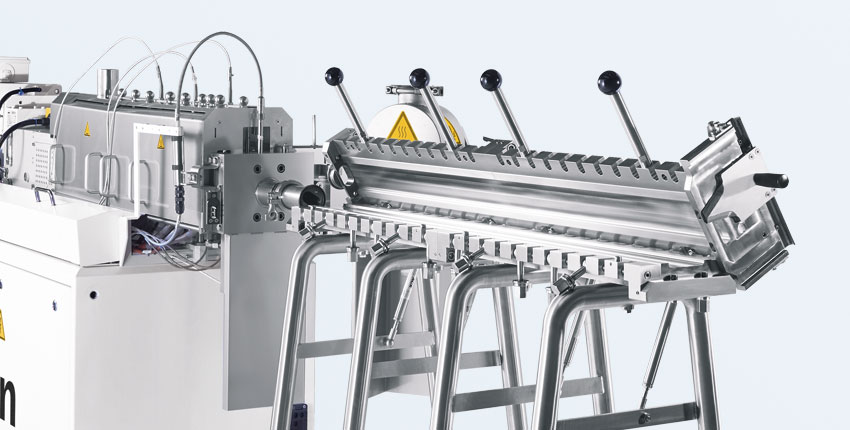

Using an adapter solution, the ZSK Food Exutruder’s discharge can be changed over from the ZGF centric pelletizer to a cooling die in as little as one to two hours. The same principle functions just as quickly in reverse when performing product changeovers from an HMMA process to TVP. The machine’s operator personnel can perform the changeover without support from an electrician.

Cleaning of the ZSK Food Extruder in Hybrid Version is important when switching plant-based protein products due to the risk of contamination. The ZSK’s twin screws have a self-cleaning profile. The screws are intermeshing and self-wiping. Therefore, there are no stagnant zones over the whole length of the process section.

ZSK Food Extruders in Hybrid Version are most useful for small to mid-scale operations, research units and start-ups in particular as they offer an ideal opportunity to enter the rapidly growing market for plant-based products. Until now, different extrusion lines were required for the production of TPV and HMMA - and thus high investments. With the ZSK Food Extruder in Hybrid Version TVP and HMMA can be produced with just one production line.

Coperion

Open navigation

Coperion

Open navigation