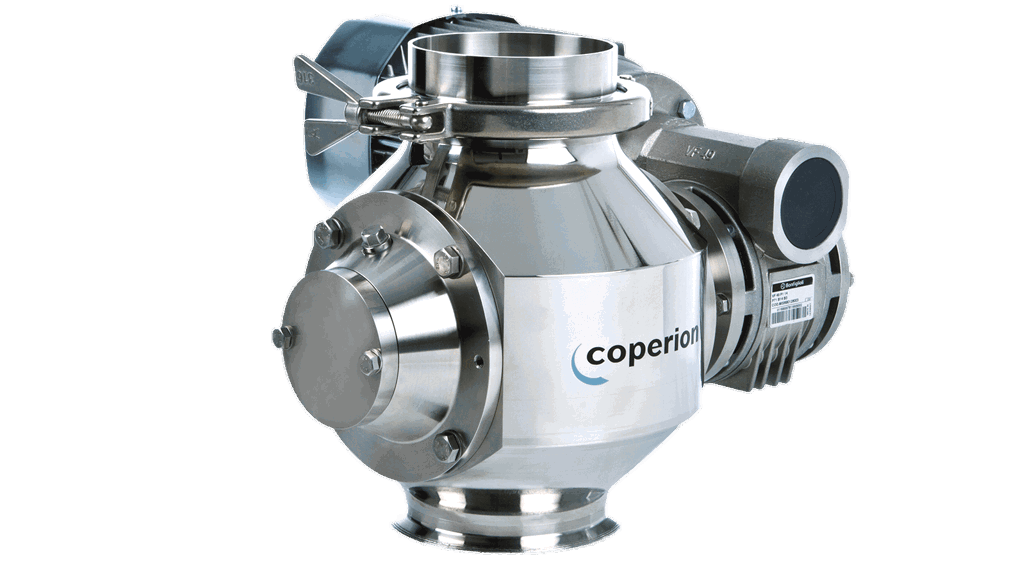

The new ZZB rotary valve was designed especially for discharging and feeding of small quantities. At the same time, its materials and design meet the increasingly high sanitary requirements.

The housing, side cover and rotor are all made from corrosion-resistant, solid stainless steel (DIN 1.4404 / 316L). Moreover, FDA-compliant PTFE seals are used, which gain broad acceptance due to their outstanding chemical resistance. The polished stainless steel surfaces (interior and exterior) prevent undesirable product deposits, thereby reducing the cleaning effort and the risk of contamination.

The standard extraction device makes handling the compact rotary valve very convenient; the rotor can be removed and installed without adjustment. Compared to conventional rotary valves, the ZZB features easy inspection and cleaning. The tri-clamp connections at the inlet and outlet also save time and increase efficiency during installation and maintenance.

The space-saving stainless steel rotary valve is available in sizes DN 80 and 100 (inlet and outlet) and perfectly suitable for applications with throughputs of up to 1.3 m³/h, pressures of up to 1 bar, application temperatures of up to 100°C and use in Ex zones.

Sign up for the Coperion newsletter to receive the latest updates

New ZZB rotary valve

Compact solution for small throughputs and outstanding sanitary requirements

Contact

-

Daniela Oehler

- email: daniela.oehler@coperion.com

- telephone: +49 751 408 767

Coperion

Open navigation

Coperion

Open navigation