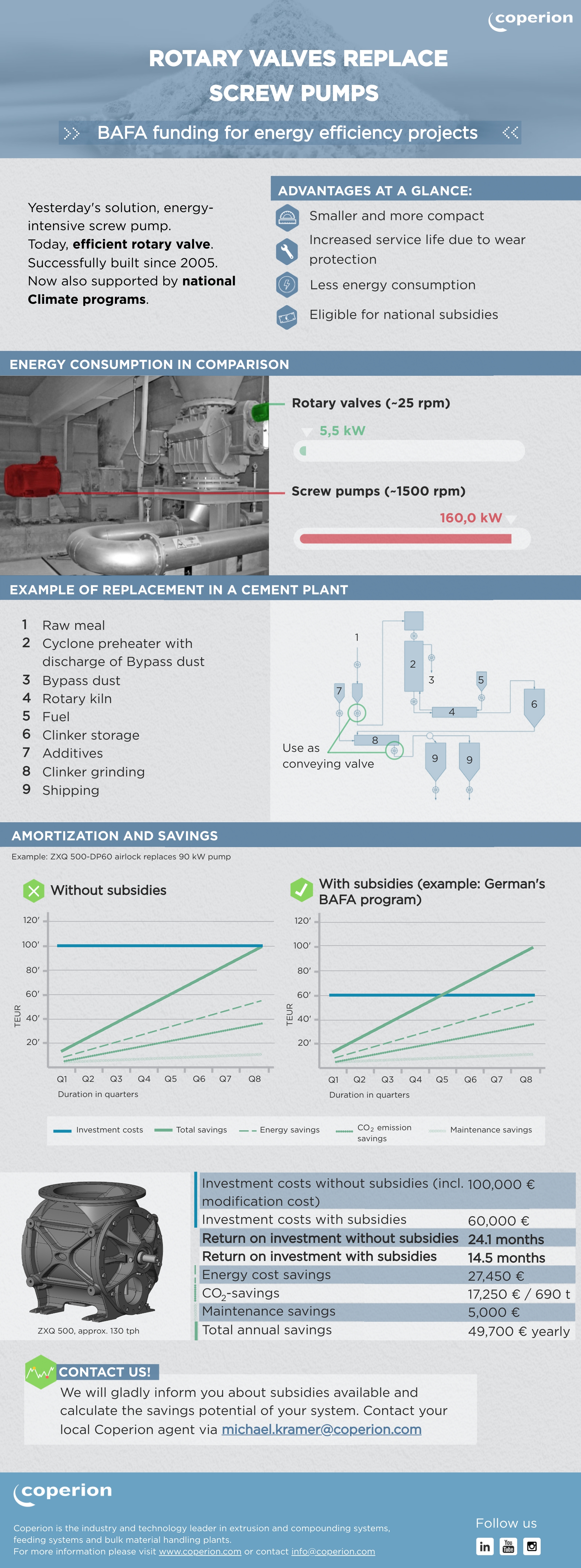

In the long term, the energy-intensive operation of screw pumps is very costly, not eco-friendly and thus requires a more sustainable alternative. A better and above all more cost-efficient option are rotary valves. In addition to their technical advantages, rotary valves are even eligible for subsidies under national climate programs. As an experienced partner of the cement industry, Coperion knows the framework conditions required for obtaining funding and advises customers who are interested in replacing their screw pumps.

Coperion's rotary valves have been successfully built and continuously improved for decades. This results in the following advantages compared to screw pumps: Rotary valves are much more compact and therefore take up less space in the plant. Moreover, our components come with wear protection leading to an increased service life of our rotary valves – even when conveying particularly wear-intensive products. Based on governmental subsidies and lower energy consumption, replacement can be financially beneficial after only a short time. As the infographic shows, rotary valves consume only a fraction of the energy normally required by screw pumps. Our project experiences have shown that rotary valves consume about 5.5 kW, whereas the energy consumption of screw pumps is 160 kW. This corresponds to an almost 30 times higher energy consumption and thus costs. Rotary valves can be used in a variety of ways as conveying elements and can thus contribute to considerable savings through longer service lives and lower energy consumption. At the same time, CO2 emissions and maintenance costs are decreased. Furthermore, with the help of governmental subsidies, investment costs can now be significantly reduced. According to our sample calculation, amortization with the subsidy takes place after just 14.5 months.

Are you interested in more information? Do not hesitate to contact us.

Coperion

Open navigation

Coperion

Open navigation