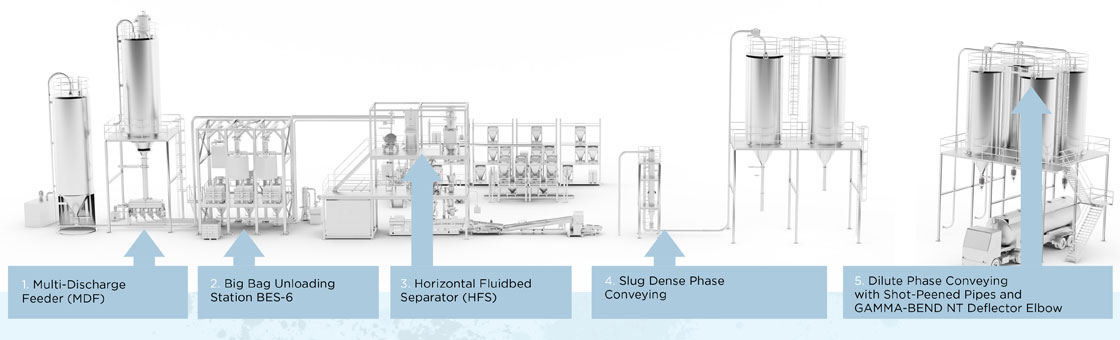

Compounding plants play a critical role in the plastics industry as well as in some chemical applications. By effectively blending and processing raw materials into more functional and application specific compounds, these state-of-the-art systems support the development of high-performance, customized materials that drive innovation and efficiency across multiple applications.

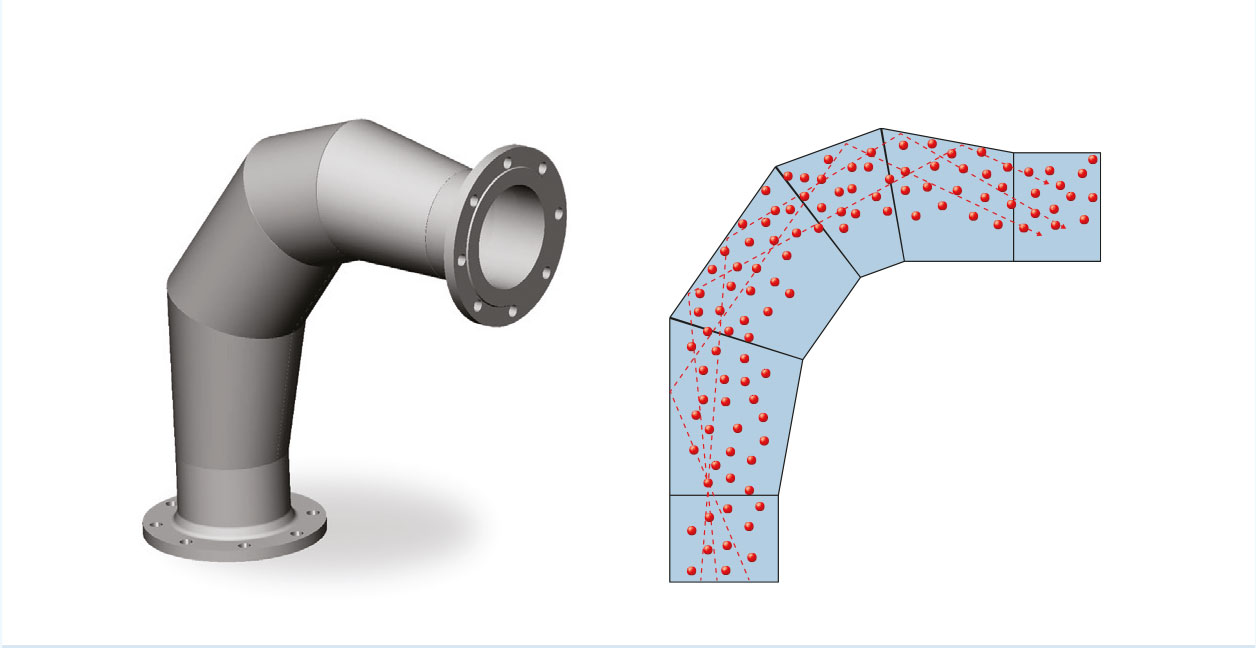

Compounding plant operators face significant challenges. Product quality must meet the highest standards of consistency. It must not be impaired by unwanted byproducts, such as fines or streamers, that can occur during the handling and processing of materials. At the same time, production lines often need to reach very high throughput rates and work with maximum efficiency to maintain highest profitability. Meanwhile, plant operators must show foresight and planning to ensure that adaptable systems are put in place to manage the processing of different material sizes and densities as demands change.

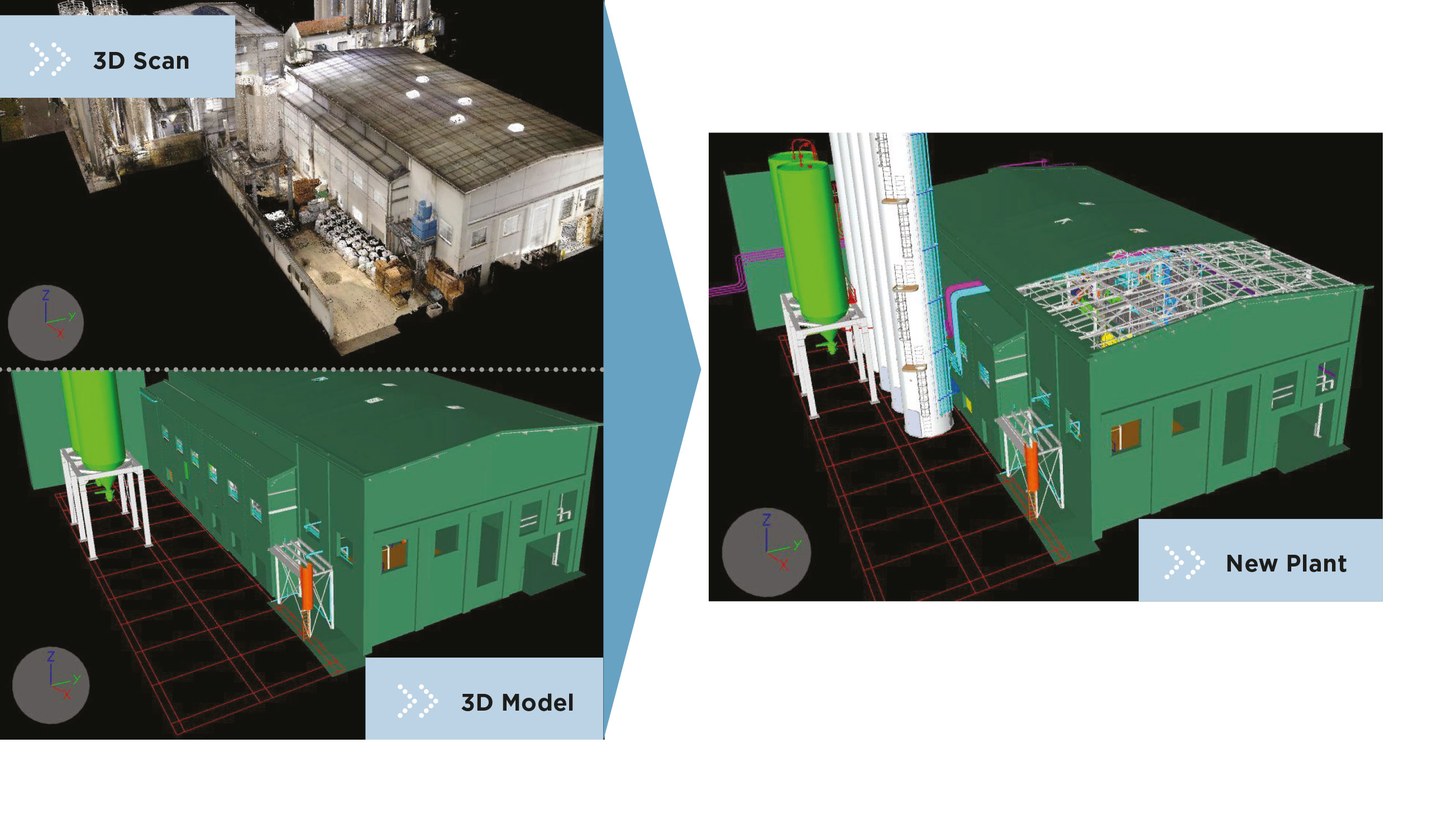

These challenges also present opportunities. Compounding plant operators can undertake targeted modernization measures to optimize performance.

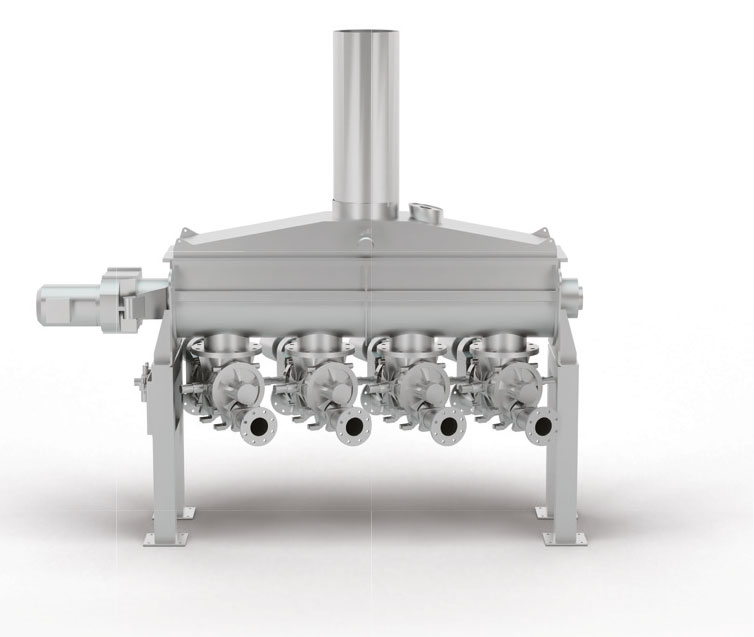

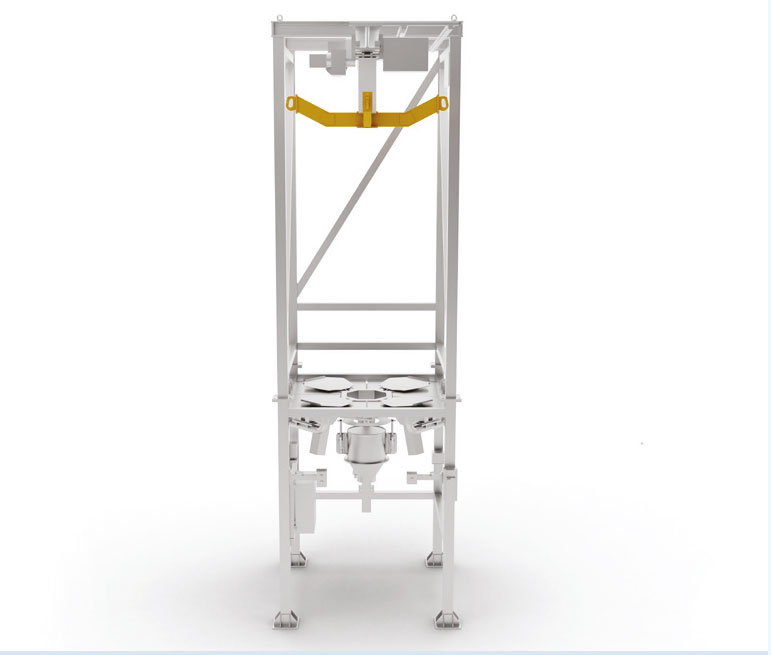

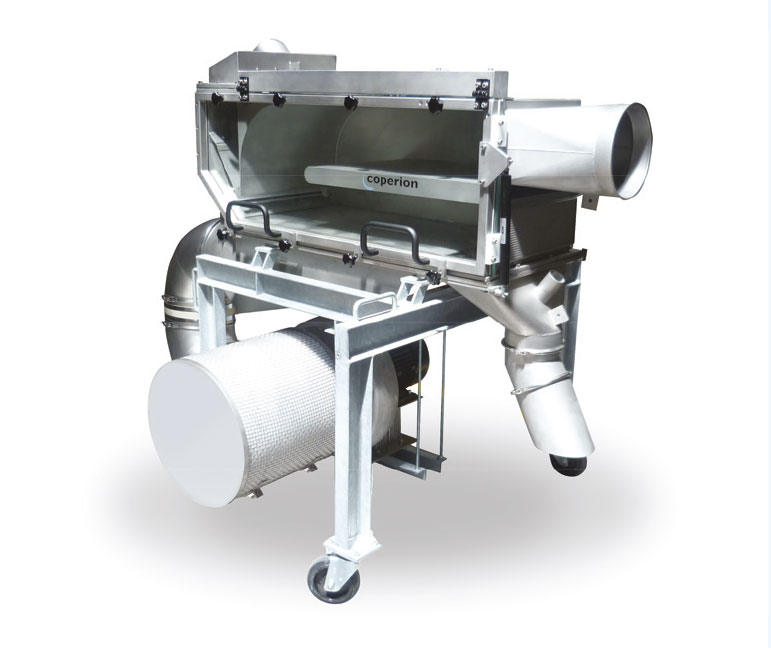

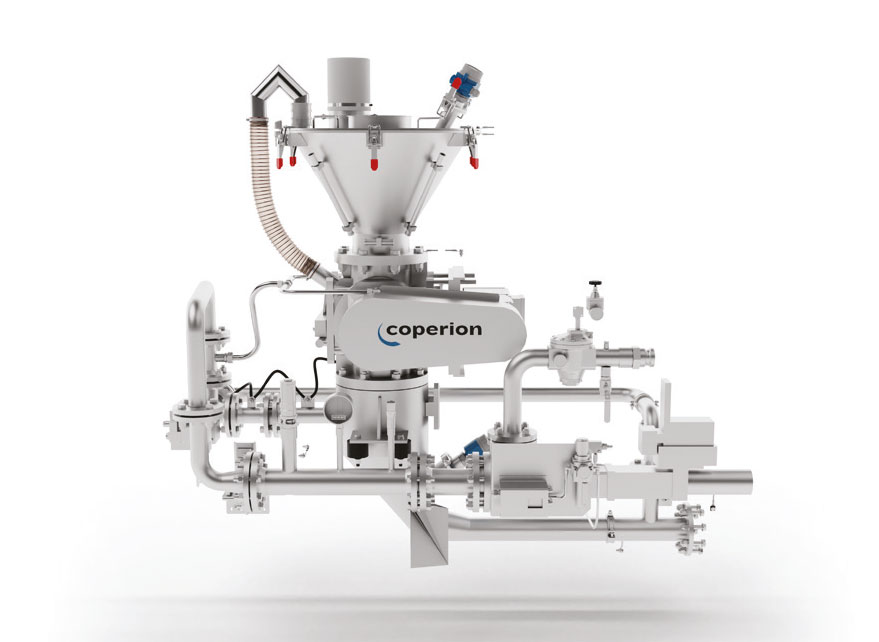

Let’s take a targeted look at the product discharge and bulk material handling technology. Modernization measures in these two areas of a compounding plant can improve product quality and the productivity of the entire system. Such investments can improve product quality as well as plant productivity and efficiency, while promoting more sustainable operations by minimizing raw material usage and waste. These measures can also help avoid the generation of fines and streamers, which will subsequently reduce downtime.

Coperion

Open navigation

Coperion

Open navigation