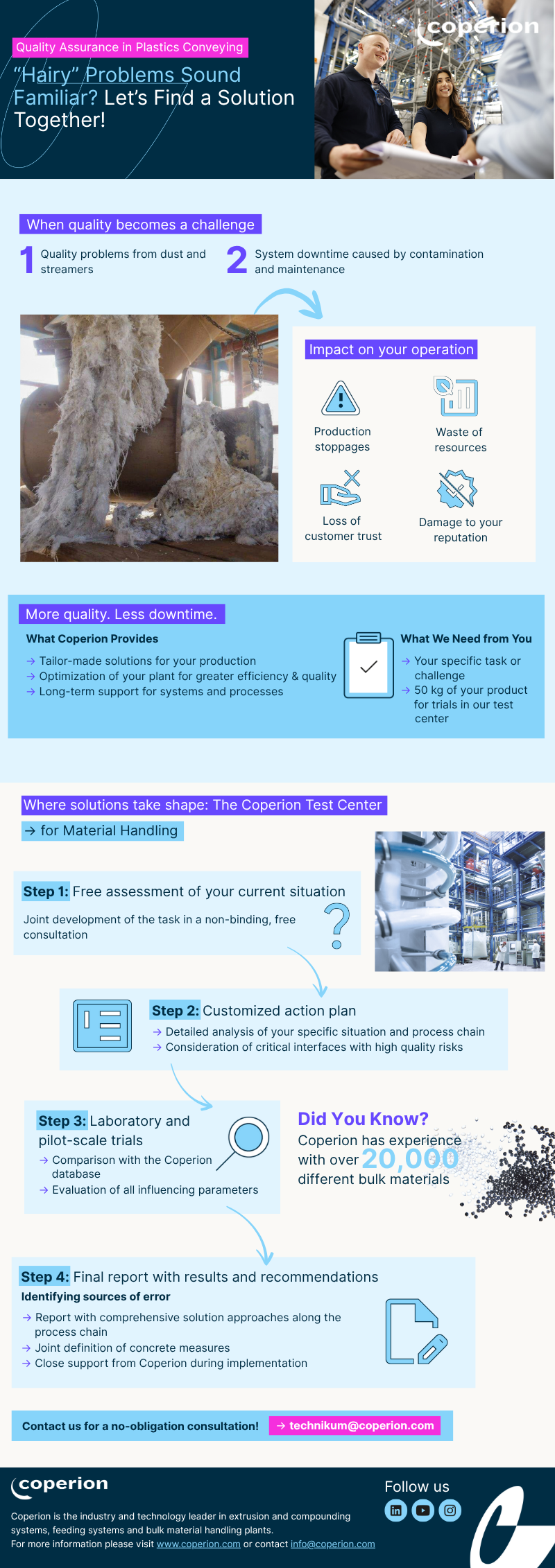

Common Quality Issues in Bulk Material Handling in Plastics Production:

- Formation of streamers (also known as “angel hair”)

- Dust generation in pneumatic conveying

- Contamination due to abrasion or foreign particles

- Visible quality fluctuations despite using identical raw materials

Quality fluctuations can occur sporadically or develop gradually – even with increased quality checks. This can significantly reduce the efficiency of your production system and result in additional costs. Furthermore, these problems often appear irregularly, are difficult to reproduce, and even harder to pinpoint. This is precisely where our structured analysis process comes in.

Analysis and Optimization of Your Plastics Conveying Process at the Coperion Test Center

Step 1: Free Initial Assessment of the Current Status

As part of a trial, our experts conduct an initial assessment of your product using approx. 50 kg of your material. The goal is to narrow down the cause of the quality issues and to define clear objectives for further action – together with you.

Based on this, you will receive either concrete solutions to your problem or, in more complex cases, an offer for an in-depth analysis. An example process may proceed as follows:

Step 2: Customized Action Plan

Our experts analyze your entire process chain, with a focus on potential risk factors. Interfaces with a higher risk of dust, streamers, or other contamination are examined in detail.

Step 3: Laboratory Analysis

Your product samples are analyzed in our lab and compared against our extensive database. We evaluate all relevant influencing factors in your process – including particle size, density, flow characteristics, and moisture content.

Step 4: Trials at the Coperion Test Center for Material Handling

Based on a customized test program, we analyze your issues under real conditions and develop a tailored solution.

Step 5: Test Report & Action Plan

Based on expert analysis, you receive a detailed report that includes:

- Root cause analysis for dust and streamer formation

- Specific recommendations for optimizing your processes and systems

- Assistance with implementation in your plant through our service team

Your Benefits: Improve Quality and Reduce Costs in Plastics Processing

Our experts won’t leave you alone with your challenging problems! We’re your trusted partner for all bulk materials and the challenges that come with them. Let’s work together to improve your production efficiency, reduce costs, and enhance your product quality over the long term.

Asking questions is free – reach out to us with your concerns or stay informed about the latest trends.

Coperion

Open navigation

Coperion

Open navigation